What is the impact of metal substrate on UV LED?

2023-12-09

In the field of UV LED substrate is a very important basic property, in order to improve the heat dissipation and service life of LED more and more people choose metal substrate.

What are the distinctive characteristics of the metal substrate?

1. Efficient heat dissipation:

The metal substrate performs well in terms of heat dissipation, ensuring the best performance and life of the UV LED. The metal material of the metal substrate is usually made of aluminum or copper and has high thermal conductivity. Prevent heat buildup and ensure that the UV LED operates within the optimal temperature range.

2. Enhance thermal conductivity:

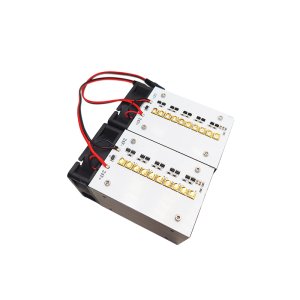

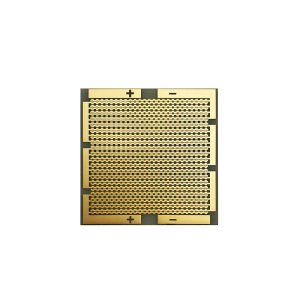

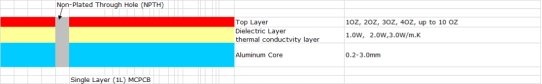

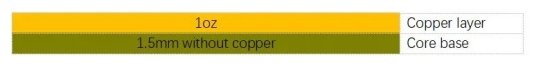

The metal substrate helps to conduct heat and effectively dissipate heat. Studies have shown that metal substrates can improve thermal conductivity, up to 10 times higher than standard FR4PCBs. Since the laminated structure of the metal substrate is different from that of the PCB, see the laminated structure comparison diagram below.

MCPCB laminated

FR4PCB laminated

3. Reliability in harsh environments:

The metal substrate is designed to withstand harsh environments, ensuring the reliability of UV LED applications. The metal core of the metal substrate provides higher mechanical strength and heat resistance. For example, the coefficient of thermal expansion (CTE) of a metal substrate can be matched to a UV LED, minimizing the risk of mechanical failure due to thermal mismatches.

4. Electrical insulation:

The metal substrate provides electrical insulation between the metal core and the circuit layer, ensuring safe and reliable operation of the UV LED. The dielectric layer is usually made of materials such as epoxy resin or thermal conductivity medium (TCF) and has a high breakdown voltage and insulation resistance. This electrical insulation minimizes the risk of short circuits or electrical interference, protecting the UV LED and the entire system from potential damage.

5. Performance optimization:

By integrating metal substrates into UV leds, manufacturers can optimize the performance of their UV LED equipment. The heat and thermal conductivity of the metal substrate allow UV leds to operate at maximum efficiency. Specific data and studies support the effectiveness of metal substrates in efficient thermal management, enabling reliable operation of UV leds even in harsh environments. With the enhanced performance provided by the metal substrate, UV LED systems can provide consistent, efficient and long-lasting UV light output, expanding the possibilities of UV applications in various industries. The application of metal substrate further solidifies its key role as a key support technology in the UV LED field.

Qingdao Yingguang UV disinfection products mainly include air sterilization, surface sterilization, water sterilization, medical sterilization and other products. The company has a professional post-doctoral team, focusing on the research of ultraviolet sterilization applications, after years of deep cultivation of the ultraviolet industry, the company has obtained a number of national invention and utility model patents. At present, a number of sterilization module products have been put into the market. For more details, please visit the company's website www.qdyingguang.com to contact the company or follow the wechat public account.